Description

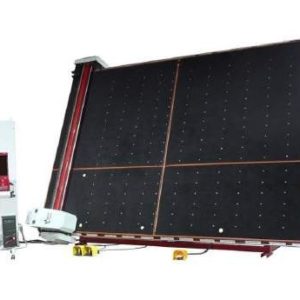

How the plotter works:

The traditional method is to use a small size cutting plotter to cut the pattern on the masking sticker, then paste the sticker onto the glass for further processing.

But now, the Vertical vinyl cutting plotter which uses CNC technology is connected to a computer using “Art Engrave” and “NC Studio” software to design drawings and control the machine. There are three motors on X, Y, Z axis to cut the Vinyl/PVC sticker on glass. The production process has totally changed, we only need to paste the sticker on glass and then cut the designs directly onto the glass which saves much time and effort. The drawings can also be designed by Corel Draw, AutoCAD, Adobe Illustrator, etc.

What are the differences between using a blade cutter and a laser cutter?

1) The laser can cut to the edge of the glass while the blade need to leave a 3 mm from each edge of the glass.

2) After surface abrading (sandblasted/acid etached), the laser is better for secondary operations such as adding additional etching on the glass surface.

3) The laser cutter is harder to control the depth of the cut on the vinyl/glass. Although it leave scratches on glass surface, but it would not affect the result for sandblasting/acid etched. The laser cut glass also can be final products. The blade can be adjusted to cut a more uniform depth and do not hurt glass