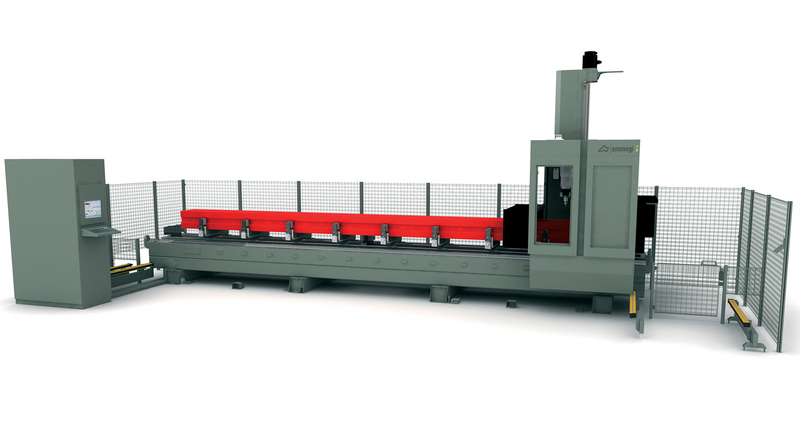

AXIS TRAVEL

X AXIS (longitudinal) (mm) 7690 /10000

Y AXIS (cross) (mm) 1210

Z AXIS (vertical) (mm) 910

A AXIS (spindle rotation) 0° ÷ 180°

POSITIONING SPEED

X AXIS (m/min) 80

Y AXIS (m/min) 64

Z AXIS (m/min) 64

A AXIS (°/min) 8100

ELECTRO-SPINDLE

Max. power rating ( S1) kW) 7,5

Max. speed (rpm) 20000

Max. torque (Nm) 8,2

Tool taper HSK-63F

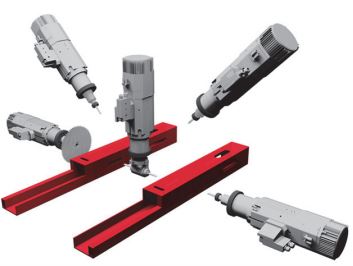

AUTOMATIC TOOL MAGAZINE ON BOARD SLIDE

Number of tools in magazine 9

Max. tool size loadable in the magazine Ø=63 L=180

Max. blade size loadable in the magazine Ø=250

Max. number of angle machining heads loadable in the magazine 2

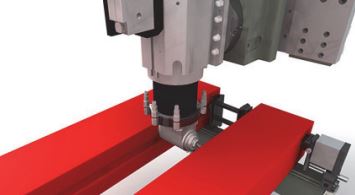

MACHINABLE FACES

With straight tool (top face and side faces) 3

With angle machining head (top face, side faces and ends) 1 + 2 + 2 + 1

With blade tool (top faces, side faces and ends) 1 + 2 + 2

MACHINING CAPACITY (Base x Height x Length)

Max. workpiece size, machinable on 1 face, held in standard vice with tool length (A) L=50mm plus toolholder B)

L=138,5mm

640 x 380 x 7700

640 x 380 x 10000

Max. workpiece size, machinable on 1 face, held in special fixture with tool length (A) L=50mm plus toolholder (B)

L=138,5mm

900 x 380 x 7700

900 x 380 x 10000

Max. workpiece size, machinable on 3 faces with tool length (A) L=50mm plus toolholder (B) L=138,5mm

460 x 380 x 7700

460 x 380 x 10000

Max. workpiece size, machinable on 5 faces with tool length (A) L=50mm plus toolholder (B) L=138,5mm and angle

tools L=60mm

460 x 380 x 7400

460 x 380 x 9730

TAPPING CAPACITY (with tap on aluminium and through hole)

With compensating chuck M8

Rigid tapping M10

WORKPIECE CLAMPING

Standard number of air-operated vices 6

Max. number of air-operated vices 12

Max. number of vices per area 6