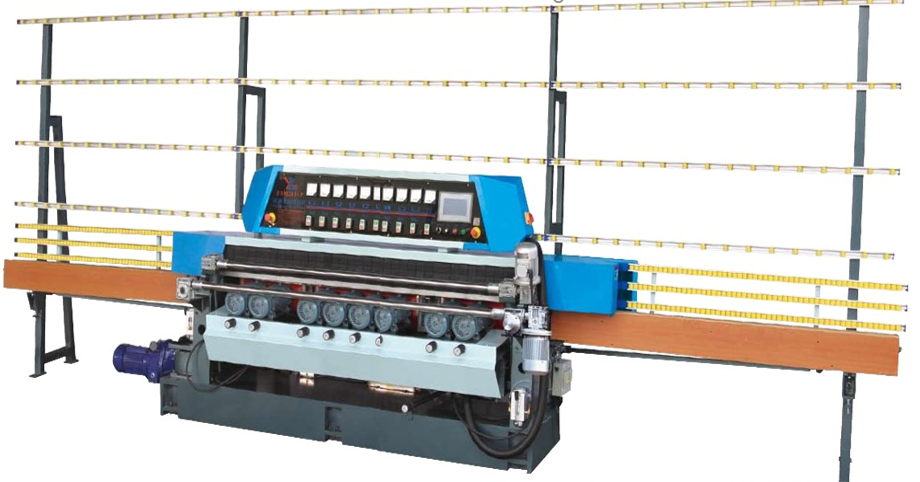

- Base、Beam、Swing frame、upright all is used by high-quality castings, strong and stable body.

- ABB international brands grinding motor, 2.2 KW wide range stepless speed changer, frequency adjustment.

- The front and rear delivery pad is used 40cr steel and 55-degree high-frequency hardening

to its degree of hard wear.

- Aluminum scaffolding, timing belt transmission.

- stainless steel water tank、there are two oil pump,it control by hand.

-

- Electrical appliances used the Tengen brand and so on high-quality product.

- Rough grinding wheel, finish grinding wheel, polishing wheel: it all use China high-quality

wheel and Italy wheel.

- Full-automatic control, it is suitable for max bevel width market.

- This machine can accord customer requirement to design.

Description

This machine is a nine-head bevel and bottom grinding machine, it can complete rough grinding and fine grinding in one time, the polished effect is similar to a mirror surface, with accurate ground angles. Control system uses PLC control, automatic, manual conversion. Man-machine interface clearly shows that the glass thickness, width and angle of hypotenuse, and the remaining glass thickness and various parameters, such as processing speeds, transmission speed using variable frequency adjustment.

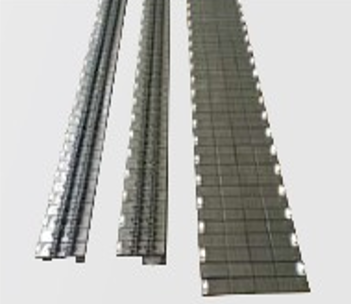

Chain plates are made of thicker steel plates and the slide gibs are made with a number of special processing techniques with such features as superior abrasion resistance, deformation resistance, and stable operation etc. The motor of the machine has a solid body, high precision, low-power consumption, suitable for beveling and milling processing of large quantities of glass parts