| Max. workable glass sheet | mm. 3700×2600 |

| Workable thickness | From 2 to 19 mm (0.079 to 0.748 in). You can cut every kind of glass (except tempered ones), included pressed and net ones. This is allowed by a spring system, mounted on cut head, to counterbalance the glass sinkings. |

| User interface | On a Windows7 base, control of three interpolated axles, easy-to-use, with icons of the relevant command. |

| Topple of the work surface | Hydraulic with 2 cylinders with anti-fall safety valves. A valve splits the oil flow up on the hydraulic power cabinet, to guarantee a long duration of the simultaneousness of going up and down of the pistons. This avoids shakes and

vibrations of the work surface through the time. |

| Data entry | By alphanumeric keyboard. You can use both hardware keys, CD Rom, serial and network connections. |

| Air cushion device | Air cushion generating fan featuring a

throttle valve for the immediate closing of the air flow at switching off. |

| Squadratura della lastra | Squaring blocks automatically go up and down. In case of Shape copy device the alignment of glass sheet is automatic |

| Work surface | Made in very hard wood, covered with woollen felt of high density and compactness, 4 mm thick (0.157 in). |

| Cutting bridge | The cutting bridge is made in extruded heavy aluminium for a robotics use. Aluminium has got the same characteristics of torsion and flexibility of

steel, with the advantage to be lighter. The whole system is much less stressed during the acceleration and deceleration phases, assuring a minimum wear and tear. In fact all the most advanced robotics is made in aluminium. |

| Cut trolley | Made in aluminium. The cutting head is made with special machines with hundredth tolerances. Going up and down system of the cutting head is guided by a system with re-circulation of ball- |

| bearings, to reduce the friction as much as

possible and guarantee the cutting head reply to glass sinkings. |

|

| Sliding systems | Sliding systems both of the bridge and the

cutting head are made with a pinion-rack system. The racks and the pinions are tempered and refaced. The racks are 35 mm (1.378 in) thick. They have a ± 0.04 mm (± 0.00157 in) tolerance with 1.20 mt (47.24 in) length. The teeth racks are turned towards low. One pinion are placed on the two sides of the bridge (four in all), to keep always perpendicular the bridge to the cutting table during the acceleration and deceleration phases. |

| Safety of the glass presence | A sensor is placed on the cutting head, to stop the machine in case of lack of glass sheets. |

| Safety regulations | The machine has got a (European Community) mark, so it bears witness of machine directive. |

| Safety systems | Photocells system to protect the users. They are controlled by an electronic power unit and they are of 4 class (maximum safety class). |

| Electro mechanics safety | As per Machines Directive ( ) |

| Management of mechanisms | (immediate and controlled braking of the bridge and the cutting head, as soon as an emergency occurs) |

| Overall sizes | 4250×3280 |

| Weight | Kg 2.500 |

| Work surface height | Adjstable from 880 to 970 mm (34.65 to 38.19 in) |

| Maximum installed power | Kw 10 |

| Maximum speed of the bridge and

cutting head, maximum accelerations and decelerations |

Max. speed 150 m/min Max. acceleration 0.7 sec. from 0 to max. speed (1.75 m/sec2) (5.74 ft/sec2)

Max. deceleration 0.5 sec. From max. speed to 0 |

| Complete rocking time | From 45 to 50 seconds |

| Max. shifting of the theorical

profile, set on CN for rectilinear works (glass 3 mm thick) (0.118 in.) |

+/- 0.08 mm (0.00315 in) |

| Max. shifting of the theorical

profile, set on CN for shaped works (glass 3 mm thick) (1.118 in.) |

+/- 0.11 mm (0.00433 in.) |

| Max. difference in length between

two diagonals for an area bigger than 2mq (21.528 sq.ft.) (glass 3 mm thick) (1.118 in.) |

0.5 mm (0.0196 in) |

| Rectilinearity tolerance (glass 3 mm

thick) (1.118 in.) |

+/- 0.20 mm |

| Vinyl cutting | Included |

| Cutting bars | 2 cross-bars and 1 longitudinal |

| Pistons for glass sheet separation (option) | two for loading with any kind of pliers |

| Shape copy | Laser System for copying of the shapes, of

any material, with double control of the correct survey of the points. It is used for automatic alignment of the glass sheet. |

| Post-sale service | Tele-service via modem for a total control of the machine (free without any fee) |

| Protection against interruptions of

tension |

UPS (uninterruptible power system) to protect the computer and the CN from sudden changes of electricity power |

| Optimisation program | Optimization software Optima Included a bidimensional Cad, 250 parametric shapes library, |

| Laminated Glass | Laminated glass cutting even in shape,

with a +/- 0.2 mm (0.00787 in) precision. |

| Spare parts | Endowment with cutting wheels and oil cutting, Self-installing softwares supplied with the machine, in case of non-operating hardware. |

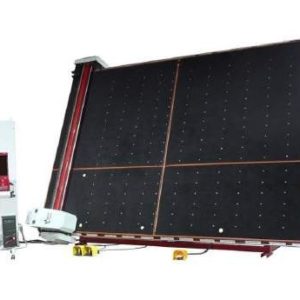

Computerized ,straight &shape cutting table – MV G370

Equipped with: Control panel with incorporated independent personal computer, software packet with optimization program developed in Windows 7 with 250 parametric pre-constructed shapes, user graphic interface for the managing of the cutting cycle and machine monitoring, hydraulic tilting surface, air cushion, ventilator for the movement of the sheet on the surface,, double zero for the cutting of laminated glass (shaped too), security systems following the laws, handbook in German.

Description

OPTIONS INCLUDED IN THE PRICE

- Small pistons for detachment of the sheet when the surface is completely lifted

- CAD package for free drawing

- Shape scanner on the cutting head

- Tele assistance with modem

- Cutting Vinyl system

- UPS protector

- Low-e removal system