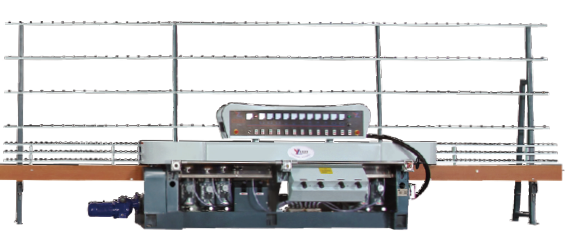

The 11motors machine is mainly used for grinding bottom edges and large edges of flat glass, its grinding motor are very reasonably distributed, 5 pcs of which are used for grinding bottom edges, 4pcs for grinding 45-degree sharp edges, it can be used for precisely grinding flat bottom edges and 45-degree sharp edges of glass. The machine has highly practical, simply operation, it is suitable for professional furniture, doors, windows, kitchen, craft, construction glass grinding.

Main technology parameter

Description

Main functions of the automatic vertical glass transfer table (many functions are in

the leading of our industrial)

- The transmission of input and output parts are separate control, the part of input,output,transfer arm are control of independent variable frequency motor. There is no need to leave a large space before and after the glass. Similar to the speed of manual to input the glass, improve the efficiency and safety of production.

- Automatic reduction in glass landing, the transfer arm has automatic reduction function, protection of glass without break the edge.

- Loading arm fell back quickly and high efficient to connect the next piece of glass;

- Instead of the input and output guide of original machinery , save area and omitted the wastage of the original conveyor belt;

- The input and output part of transferring table can be add the conveyor chain or synchronous belt to auxiliary conveying glass;

- The transmission parts are divided into two sections, and the lifting function of the output part can adjust the amount of glass grinding.

- Transferring table is control by PLC, touch screen operation;

- Configurable control cabinet, overall control of the processing speed and glass thickness.