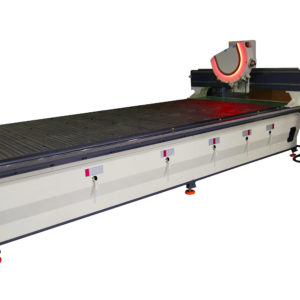

AXIS TRAVEL

X AXIS (longitudinal) (mm) – 4300

Y AXIS (cross) (mm) – 270

Z AXIS (vertical) (mm) – 300

ELECTRO-SPINDLE

Max. power rating (S1) (kW) – 5,5

Max. power rating (S1) (kW) (optional) – 7,5

Max. speed (rpm) – 20000

Tool taper – HSK 63F

AUTOMATIC TOOL MAGAZINE

Max. number of tools in the tool magazine – 4 standard / 8 optional

Max. number of angle machining heads loadable in the tool magazine – 2

Max. blade diameter loadable in the tool magazine (mm) – Ø 180

FUNCTIONS

Multi-piece operation

MACHINABLE FACES

With straight tool (top face) – 1

With angle machining head (side faces and ends) – 2 + 2

With blade tool (side faces and ends) – 2 + 2

TAPPING CAPACITY (with tap on aluminium and through hole)

With compensating chuck – M8

Rigid tapping (optional, only with 7.5 kW electro-spindle) – M10

WORKPIECE CLAMPING

Standard number of vices – 4

Max. number of vices – 6

Automatic vice positioning through the X axis

Description

1- Vices

The machine software, in relation to the work piece length and machining operations, is able to determine the exact

position for each vice set under fully safe conditions. The automatic vice positioner allows engaging each vice set and traversing it via the slide movements. This operation is performed at max. speed and with great accuracy, thus avoiding long down times and risks of collision hence the machine can easily be used also by less skilled operators.

2- Electro-spindle

The high torque electrospindle 5.5 kW (S1), which also comes in the 7.5 (S1) version, allows heavy duty machining

typical of the industrial sector. It can be used on certain types of extruded steel sections as well as on aluminium profiles thanks to the availability of a lubrication system, programmable via software, whose double tank allows use of both minimum quantity oil lubrication or spray mist with oil emulsion.

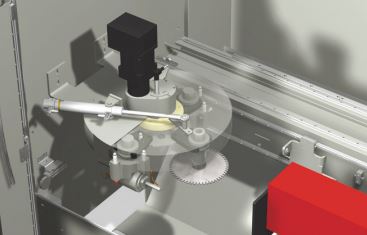

3 – Tool magazine

The new tool magazine of circular shape, is designed to take up less space. Not only does it allow positioning of very large extruded sections in the machine, it also allows very quick tool change. The metal protective cover offers maximum protection of the tool tapers against swarf and accidental collision. The tool magazine can hold up to

4 (8 on request) tool holders with their corresponding tools, which can be configured as required by the operator.

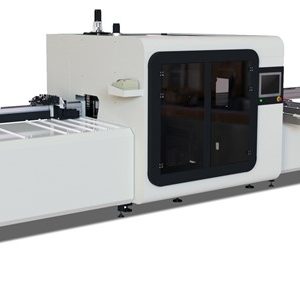

4- Operator interface

The new version of the control system, with pendant interface, allows the operator to view the monitor from any

position, as it is can be pivoted about the vertical axis. The operator interface features a 15″ touchscreen

provided with all the necessary USB connections for remote interfacing with the PC and N/C. It is also provided with a control panel, mouse and keyboard. It also has predisposition for connection of a barcode reader and remote control panel. An easily accessible front USB socket replaces the floppy disk and CD-ROM drives.

5- Angel machining head lubrication

The electro-spindle incorporates an adapter flange with quick-connect fittings in order to accommodate the

lubrication system for the angle machining attachments thus ensuring correct lubrication of the tools during cutting.