MACHINE FEATURES

X axis electronic control ●

X axis positioning speed 25 m/min

Mobile head position detection via direct measuring system with absolute magnetic band ●

Mobile head inclination detection via direct measuring system with absolute magnetic band ●

Intermediate angles electronic control ●

Max. external inclination 15°

Max. internal inclination 45°

Hydropneumatic blade advancement ●

Useful cut, according to model (m) 5 / 6

Widia blades 2

Blade diameter 550

Blade motor power (kW) 2,2

Electronic measurer of profile depth ○

SAFETY DEVICES AND PROTECTIONS

Pneumatically-operated front local protection ●

POSITIONING AND BLOCKING OF PROFILE

Pair of horizontal pneumatic clamps with “low pressure” device ●

Pair of vertical fastening horizontal clamps ○

Pair of additional horizontal clamps ○

Mechanical intermediate profile support ●

Roller conveyor on mobile head with mechanical interlocking profile supports ○

Profile support roller conveyor on fixed head for profile input from left ○

Pneumatic reference stop on mobile head for profile input from left ○

Description

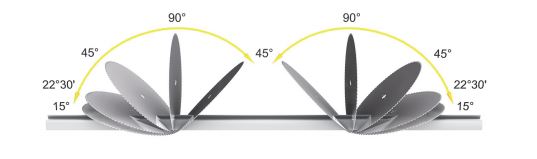

1- Virtual axis of inclination of the cutting units

The inclination of each head, up to 15° outwards and 45° inwards for both the aluminium and PVC versions, is implemented by means of two circular guides positioned on four pairs of steel wheels. This solution, subject to patent, allows to eliminate any cutting area obstruction, with the advantage of positioning and blocking the profile and offers greater rigidity to traditional systems. Positioning via absolute magnetic band eliminates the necessity of the axes reference and connected cycle times.

2- Profile blocking

With the large availability of space allowed by the virtual axis, the profile is blocked for cutting extremely precisely and safely by two horizontal hold-down devices. For the necessity of vertical blocking, particularly for special cuts, a patented horizontal hold-down device is available, which allows vertical blocking of the profile.

3- Head Protections

The automatic head protections, made of scratchproof polycarbonate, are driven by a pneumatic cylinder with an anticrushing device which resets the pneumatic load during closing. They are mounted on a side sliding system

to safeguard the operator during every cutting operation.

4 – control

The ergonomic and extremely advanced control panel uses a 10.4” touch screen display and completely customised software and is full of functionalities developed specifically for this machine, in Microsoft Windows® environment. The machining cycle is optimised by the creation of the cutting lists, thus allowing the reduction of waste and the decrease in times for the piece load-unload.

5- Load and unload

Precision can be equipped with roller conveyor on mobile head, for standard load and unload or on fixed head for load from left side. A pneumatic stop device on the mobile head is available to facilitate positioning of the profile in this loading mode.